Essential Overview to Undercarriage Parts for Heavy Equipment

When it comes to hefty devices, the undercarriage plays a vital function in making certain smooth and reliable operations. Recognizing the detailed information of undercarriage components is necessary for making the most of the lifespan and efficiency of your machinery. From track chains to rollers and idlers, each element adds to the general functionality of the tools. Looking into the specifics of gears and various other undercarriage aspects provides invaluable insights into upkeep methods that can significantly influence the durability of your hefty machinery. By grasping the significance of these parts and their maintenance demands, drivers can maximize the efficiency and longevity of their devices, ultimately resulting in set you back financial savings and enhanced functional efficiency.

Relevance of Undercarriage Parts

Understanding the essential function that undercarriage parts play in the performance and durability of heavy devices is vital for efficient maintenance and operation - undercarriage parts. The undercarriage elements develop the structure on which the whole maker runs, sustaining the weight of the tools, providing stability, and absorbing shock loads throughout operation. A well-kept undercarriage not only makes sure smooth procedure yet also contributes significantly to decreasing downtime and repair work costs

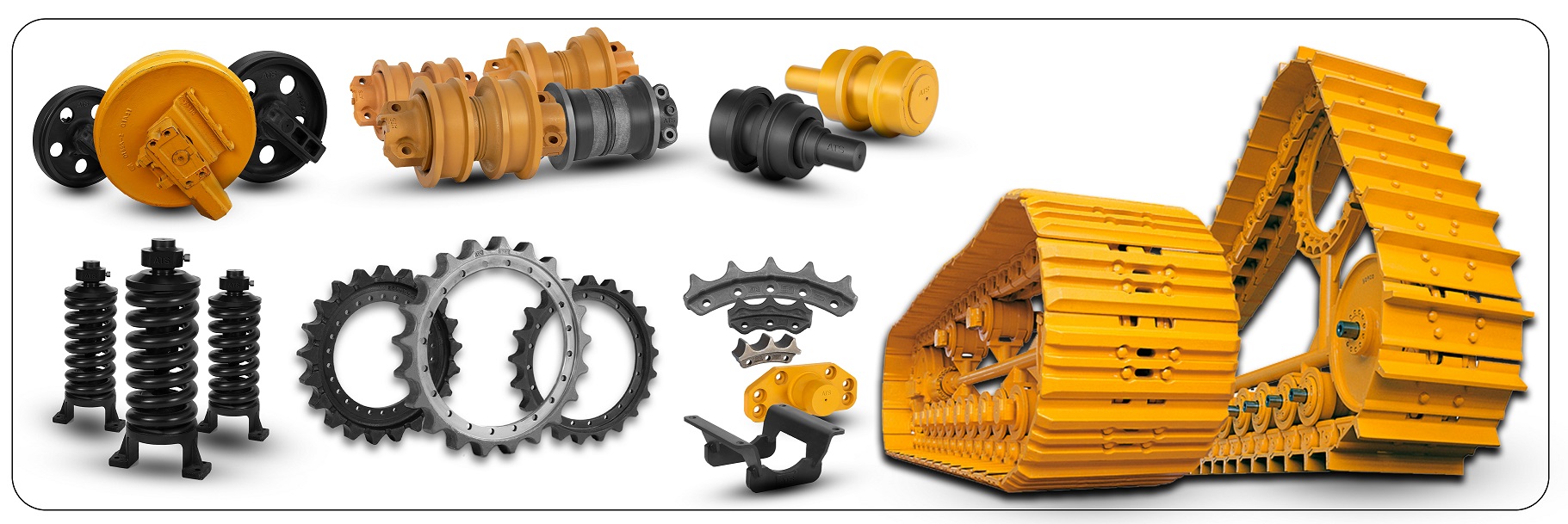

The undercarriage includes different crucial parts such as track chains, track shoes, sprockets, idlers, rollers, and track frames. Each of these elements plays a crucial function in the general performance of the tools. The track chains and track footwear help in offering grip and assistance, while the idlers and gears aid in driving the tracks smoothly. Regular inspection, prompt upkeep, and replacement of worn-out undercarriage components are critical to stop break downs and maximize the life expectancy of the heavy tools. Essentially, purchasing top quality undercarriage components and ensuring their correct care is essential for optimum performance and durability of hefty machinery.

Kinds Of Track Chains

Track chains are crucial elements of heavy tools undercarriages, offering the essential traction and assistance for efficient operation. There are mostly two types of track chains made use of in heavy devices: secured and oiled track chains (SALT) and dry track chains. Sealed and lubricated track chains are commonly located in modern hefty equipment. These chains are pre-lubricated and sealed to stop dirt, debris, and dampness from entering the chain joints, making sure smooth operation and expanding the chain's lifespan. On the other hand, completely dry track chains require regular hands-on lubrication to maintain optimal performance and protect against early wear.

Function of Rollers and Idlers

Rollers and idlers play an essential function in supporting and guiding the track chains of hefty tools undercarriages, contributing to the general security and efficiency of the machinery. Idlers, on the Read More Here various other hand, overview the track chain and assistance maintain appropriate stress throughout the undercarriage system.

With each other, rollers and idlers work in consistency to make certain that the track chain remains in location, also on harsh surface, enhancing the equipment's performance and durability. Appropriate upkeep and normal evaluation of idlers and rollers are necessary to avoid premature wear and possible malfunctions, eventually maximizing the performance and lifespan of hefty tools undercarriages.

Understanding Sprockets

One important facet of sprockets is ensuring correct positioning and tension to stop premature wear and damages. Misaligned gears can cause irregular wear on the track chain, bring about reduced performance and prospective safety and security dangers. Regular maintenance and inspection of sprockets are vital to determine any type of signs of wear or misalignment without delay.

Furthermore, gears come in different dimensions and tooth configurations, relying on the specific heavy tools and its intended usage. Appropriate choice of gears based on the equipment's specs is vital to make certain optimal efficiency and long life of the undercarriage system. Understanding the function of gears and their upkeep requirements is important for taking full advantage of the efficiency and lifespan of hefty devices undercarriages.

Maintenance Tips for Longevity

To make sure the prolonged durability and optimum functionality of heavy equipment undercarriages, persistent upkeep practices are essential. On a regular basis evaluating undercarriage components such as track footwear, rollers, idlers, and gears for damage is crucial. Replace any type of worn or damaged elements quickly to stop more damages to the undercarriage system. Appropriate track tension visit here modification is likewise important for minimizing early endure undercarriage parts. Over-tensioning can result in enhanced tension on the components, while under-tensioning can cause track slippage and accelerated wear. Additionally, maintaining the undercarriage tidy from particles accumulation, mud, and other contaminants can help prevent deterioration and expand the life expectancy of the parts. Greasing the undercarriage parts at recommended intervals will certainly likewise decrease friction and wear. Organizing regular upkeep checks with qualified technicians can recognize potential concerns early on and address them before they intensify, ultimately making best use of the durability of heavy devices undercarriages. undercarriage parts.

Verdict

In final thought, undercarriage components are crucial components for hefty tools, playing crucial roles in maintaining stability and functionality. Proper care and attention to undercarriage components are vital to making the most of devices life expectancy and efficiency.

The undercarriage consists of various essential components such as track chains, track footwear, sprockets, idlers, rollers, and track frameworks. The track chains and track footwear aid in supplying traction and assistance, while the idlers and gears aid in driving the tracks smoothly (undercarriage parts). There are largely 2 kinds of track chains made use of in heavy devices: sealed and oiled track chains (SALT) and completely dry track chains. Correct option and upkeep of track chains are critical to make certain the general performance and long life of heavy equipment undercarriages

Gears are important components of hefty devices undercarriages, accountable for moving power from the machinery to the track chain.

Comments on “Boost Productivity: How Upgrading Undercarriage Parts Can Enhance Efficiency”